-

Phone

86-539-7****

-

Address

-

E-mail

LatestProducts

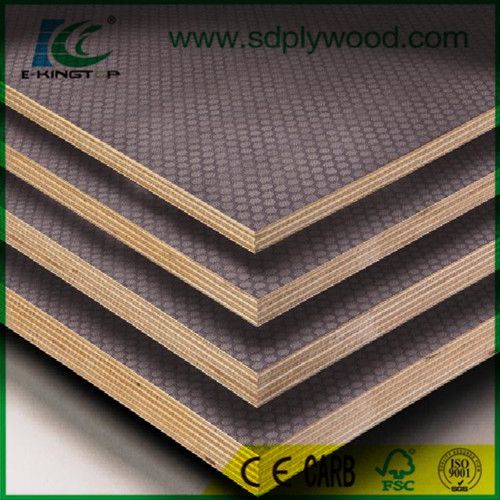

Building Material Shuttering Plywood for Construction

Plywood, Film Faced Plywood, Building Material

Description

Basic Info

- Model NO.: film faced plywood

- Grain: Iregular Grain

- Bonding Strength: Ⅲ(Nc)

- Formaldehyde Emission Standards: WBP

- Place of Origins: China

- Usage: Indoor, Outdoor

- Factory: Yes

- Payment: T/T; L./C at Sight

- Trademark: E-kingtop

- Specification: 1220x2440x18mm

- HS Code: 4412321090

- Material: Poplar

- Core Polywood: Callular Board

- Plywood Type: 13-Ply

- Specifications: 1220*2440*18mm

- Grade: Excellent Grade

- Size: 1220X2440X12-18mm

- Quality: Two Time Inspection

- MOQ: 1X40FCL

- Transport Package: Wood Pallet

- Origin: Linyi

Product Description

Building Material of Film Faced Plywood From Linyi Factory

Tested Item Type:Poplar film faced plywood 18mm

- F/B:Brown Film /Black Film/Printed logo Film

- Thickness: 12-18mm

- Core:Poplar/Harwood/Combi

- Glue:MR/WBP

| Product Name | Film Faced Plywood |

| F/B(Color of film) | Black film, Dynea Brown film,red film, anti-slip film, logo&without logo |

| Film Weight | 120g/m2; 240g/m2 |

| Grade | Two hot-press with sanding ; One hot-press without sanding |

| Core | Poplar ,Hardwood, Combi , Pine ,Birch,, Finger Joint etc |

| Density(kgs/m3) | Poplar :about 530; Hardwood:about 600; Birch:about 690 |

| Glue | MR, WBP , MELAMINE ,Phenolic WBP , |

| Size(mm) | 915x1830,1200x2400,1220x2440,1250x2500,1500x2500,1500x3000 |

| Thickness(mm) | 6.5,9,12,15,18,20,21,24,27,30,35 etc or as request |

| Processing of edges | By waterproof paint in different colors as request( brown , red, black ) |

| Moisture Content | 8-13% |

| Loading Quantity | 20FCL:8 pallets, 21; 40GP, 16pallets, 42m3;40HQ,18 pallets,52m3 |

| Certificate | CARB, CE, ISO9001,ISO14001, FSC,SGS,SONCAB |

| MOQ | 1*40HQ |

| Price Terms | FOB, CIF, CFR ,EXW |

| Payment Terms | T/T, 100% Irrevocable L/C at sight |

| Delivery Time | Within 20 days after order confirmed |

| Supply Capacity | 6000CBM/Month |

| Usage | Can be widely used for concrete in construction or truck floor etc |

| Package | Loose package, standard export wood pallets |

| Remarks | Top class equipment with top class produce technique; Credit first, fair trading |

Tested Item Type:Poplar film faced plywood 18mm

| No. | Property | Unit | Test Method |

Value of Test |

Result | |

| 1 | Moisture Content | % | EN 322 | 8.4 | Check out | |

| 2 | Density | Kg/m3 | EN 323 | 530 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | Max: 1.40 Min: 0.70 |

Check out |

| Damage Rate | % | 74 | Check out | |||

| 4 | Bending Modules of Elasticity |

Longitudinal | Mpa | EN 310 | 5215 | Check out |

| Lateral | 4796 | Check out | ||||

| 5 | Bending Strength N/mm |

Longitudinal | Mpa | 52.74 | Check out | |

| Lateral | 43.55 | Check out | ||||

| 6 | Cycle Life | About 8-15 Repeated Using Times According to Projects by Formwork Application |

||||

| Company Advantage: | |

| QC of Quality | Two time inspection and All the products best quality. Our professional QC inspectors are more than 10 years in plywood production and QC field One:In the production process,prepare core material, joint core, glue ,hot press, cold press, sanding ,covered film, painted edges etc Second:Packing and Loading .Checked the details of quality, dimension tolerance,thickness tolerance, bonding quality , core layers and structure , smooth of film,rejects defects of film like carbonization, lack of film etc. We control quality as your order requirements,then save your time and cost. |

| Advanced equipment | Imported Italy and Germany sanding machine |

| Production of capacity | 6000cbm/month |

| Delivery time | 15 days after order confirmed |

| Competitive Price | Lowest price, superior quality , prompt shipment, best service ! |

| Contact Information | |

| Contact | Henry |

| Tel/Fax | 86-539-7200968 |

| Mob | 8613884883753 |

| Web | |